Polyethylene Flame Retardant Wire Loom

Gray - 1/4" - 2" Inside Diameter - Split Wire Loom Tubing

0.0 / 5

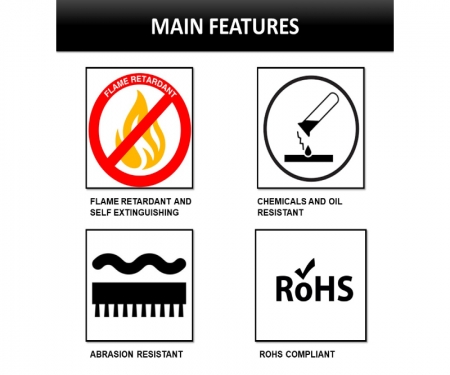

Flame Retardant Polyethylene Wire Loom Features

- MADE IN NORTH AMERICA

- Gray In Color

- Operating Temperature of -40ºF to +200ºF

- Rated V2 According To UL-94

- Self-Extinguishing,

- Excellent Flexibility

- Very Good Chemical & Abrasion Resistance

- REACH & RoHS COMPLIANT

Polyethylene flame retardant wire loom tubing is ideal for any application that requires tubing that meets flammability, and outgassing requirements. Polyethylene flame retardant wire loom is split and flexible to allow for easy installation.

While some protective tubing is rigid, our Flame Retardant Polyethylene Wire Loom from CableTiesandMore.com fully guards your vital cables and wiring from not only intense heat, but also abrasion, chemicals, impact and crushing, while retaining all the flexibility your cables had before. Being made of heat resistant & flame retardant polyethylene, the wire loom has an operating temperature of: -40ºF to +200ºF.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| |||||||||

| Nominal Internal Diameter | Dimension "A" Inside Diameter | Dimension "B" Outside Diameter | Dimension "C" Wall Thickness | ||||||

| Min | Max | Min | Max | ||||||

| 1/4" (6 mm) | 0.237” (6.02 mm) | 0.266” (6.76 mm) | 0.372” (9.45 mm) | 0.400” (10.16 mm) | 0.005” (0.12 mm) | ||||

| 3/8" (9 mm) | 0.341” (8.66 mm) | 0.380” (9.65 mm) | 0.496” (12.59 mm) | 0.526” (13.36 mm) | 0.005” (0.12 mm) | ||||

| 1/2" (13 mm) | 0.471” (11.97 mm) | 0.515” (13.07 mm) | 0.645” (16.39 mm) | 0.681” (17.31 mm) | 0.005” (0.12 mm) | ||||

| 5/8" (16 mm) | 0.603” (15.32 mm) | 0.639” (16.23 mm) | 0.802” (20.36 nmm) | 0.837” (21.26 mm) | 0.005” (0.12 mm) | ||||

| 3/4” (19 mm) | 0.707” (17.96 mm) | 0.759” (19.28 mm) | 0.950” (24.13 mm) | .989” (25.12 mm) | 0.005” (0.12 mm) | ||||

| 1" (23 mm) | 0.897” (22.78 mm) | 0.949” (24.10 mm) | 1.077 (27.36 mm) | 1.109 (28.17 mm) | 0.006” (0.15 mm) | ||||

| 1-1/4" (30 mm) | 1.199” (30.45 mm) | 1.257” (31.93 mm) | 1.446” (36.73 mm) | 1.500” (38.10 mm) | 0.006” (0.15 mm) | ||||

| 1-1/2" (40 mm) | 1.566” (39.78 mm) | 1.647” (41.83 mm) | 1.867” (47.42 mm) | 1.947” (49.45 mm) | 0.006” (0.15 mm) | ||||

| 2" (51 mm) | 1.969” (50.01 mm) | 2.038” (51.77 mm) | 2.285” (58.04 mm) | 2.388” (60.66 mm) | 0.011” (0.028 mm) | ||||

Product Description

Flexible convoluted tubing / conduit manufactured from a flame retardant polyethylene resin rated as V2 according to UL-94

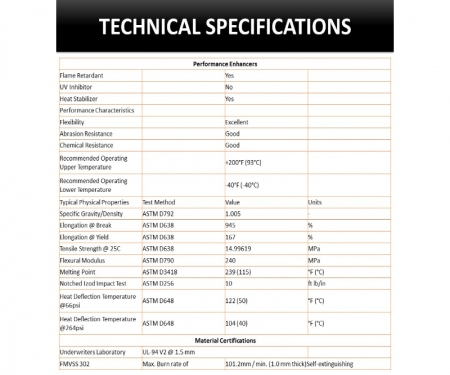

| Performance Enhancers | |||

| Flame Retardant | Yes | ||

| UV Inhibitor | No | ||

| Heat Stabilizer | Yes | ||

| Performance Characteristics | |||

| Flexibility | Excellent | ||

| Abrasion Resistance | Good | ||

| Chemical Resistance | Good | ||

| Recommended Operating Upper Temperature | +200°F (93°C) | ||

| Recommended Operating Lower Temperature | -40°F (-40°C) | ||

| Typical Physical Properties | Test Method | Value | Units |

| Specific Gravity/Density | ASTM D792 | 1.005 | - |

| Elongation @ Break | ASTM D638 | 945 | % |

| Elongation @ Yield | ASTM D638 | 167 | % |

| Tensile Strength @ 25C | ASTM D638 | 14.99619 | MPa |

| Flexural Modulus | ASTM D790 | 240 | MPa |

| Melting Point | ASTM D3418 | 239 (115) | °F (°C) |

| Notched Izod Impact Test | ASTM D256 | 10 | ft lb/in |

| Heat Deflection Temperature @66psi | ASTM D648 | 122 (50) | °F (°C) |

| Heat Deflection Temperature @264psi | ASTM D648 | 104 (40) | °F (°C) |

| Material Certifications | |||

| Underwriters Laboratory | UL-94 V2 @ 1.5 mm | ||

| FMVSS 302 | Max. Burn rate of | 101.2mm / min. (1.0 mm thick)Self-extinguishing | |

Return Policy – ( WIRE LOOM TUBING)

30-DAY RETURN POLICY

-

You may return your purchase within 30 days after delivery for a full refund less shipping charges.

-

Items must be in their original condition, not visibly used damaged, or cut.

-

10 foot Cut length wire loom orders are NON-CANCELLABLE & NON-RETURNABLE

-

GAYLORD bulk box orders NON-CANCELLABLE & NON-RETURNABLE

RETURN INSTRUCTIONS

Please Fill out our Linked RMA FORM to obtain a Return Authorization (RMA#) & Shipping instructions.

Let us know your Order ID, Name & which items you want to return.

Once we get your request we'll email you a Return Authorization and Shipping Instructions.

After we receive the return, it takes 3-5 business days for us to verify the items & process a refund. We'll refund back to your method of payment.

RETURN SHIPPING

-

Shipping charges are not refundable & customer is responsible for cost of return shipping.

-

We recommend you return via UPS, FedEx, or insured US Mail with a tracking number. Items not received by us will not receive a credit.

-

Shipping charges will apply on any exchanges.

SHORTAGE OR INCORRECT ORDERS

All claims for shortage or incorrect orders must be reported to us by phone or email within 5 business days from receipt of the order. Please mention your Purchase Order ID, Items, and your name.

DEFECTIVE PRODUCTS

Defective products must be reported to us within 30 days of delivery via phone or email.

Gaylord quantities are generally made to order, Lead times may apply.

Note: Gaylords Ship By LTL Pallet Freight Only

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Q: How do you measure the diameter of your wire loom?

A: All of the wire loom we sell is measured by its inside diameter.

Q: Is this Tubing Split

A: Yes, this tubing has a slit down its center to allow for easy installation

Q: Is this tubing flexible?

A: While this wire loom does provide ample protection it also remains easily flexible and can be manipulated.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Polyethylene flame retardant wire loom tubing is ideal for any application that requires tubing that meets flammability, and outgassing requirements. Polyethylene flame retardant wire loom is split and flexible to allow for easy installation.

While some protective tubing is rigid, our Flame Retardant Polyethylene Wire Loom from CableTiesandMore.com fully guards your vital cables and wiring from not only intense heat, but also abrasion, chemicals, impact and crushing, while retaining all the flexibility your cables had before. Being made of heat resistant & flame retardant polyethylene, the wire loom has an operating temperature of: -40ºF to +200ºF.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| |||||||||

| Nominal Internal Diameter | Dimension "A" Inside Diameter | Dimension "B" Outside Diameter | Dimension "C" Wall Thickness | ||||||

| Min | Max | Min | Max | ||||||

| 1/4" (6 mm) | 0.237” (6.02 mm) | 0.266” (6.76 mm) | 0.372” (9.45 mm) | 0.400” (10.16 mm) | 0.005” (0.12 mm) | ||||

| 3/8" (9 mm) | 0.341” (8.66 mm) | 0.380” (9.65 mm) | 0.496” (12.59 mm) | 0.526” (13.36 mm) | 0.005” (0.12 mm) | ||||

| 1/2" (13 mm) | 0.471” (11.97 mm) | 0.515” (13.07 mm) | 0.645” (16.39 mm) | 0.681” (17.31 mm) | 0.005” (0.12 mm) | ||||

| 5/8" (16 mm) | 0.603” (15.32 mm) | 0.639” (16.23 mm) | 0.802” (20.36 nmm) | 0.837” (21.26 mm) | 0.005” (0.12 mm) | ||||

| 3/4” (19 mm) | 0.707” (17.96 mm) | 0.759” (19.28 mm) | 0.950” (24.13 mm) | .989” (25.12 mm) | 0.005” (0.12 mm) | ||||

| 1" (23 mm) | 0.897” (22.78 mm) | 0.949” (24.10 mm) | 1.077 (27.36 mm) | 1.109 (28.17 mm) | 0.006” (0.15 mm) | ||||

| 1-1/4" (30 mm) | 1.199” (30.45 mm) | 1.257” (31.93 mm) | 1.446” (36.73 mm) | 1.500” (38.10 mm) | 0.006” (0.15 mm) | ||||

| 1-1/2" (40 mm) | 1.566” (39.78 mm) | 1.647” (41.83 mm) | 1.867” (47.42 mm) | 1.947” (49.45 mm) | 0.006” (0.15 mm) | ||||

| 2" (51 mm) | 1.969” (50.01 mm) | 2.038” (51.77 mm) | 2.285” (58.04 mm) | 2.388” (60.66 mm) | 0.011” (0.028 mm) | ||||

Product Description

Flexible convoluted tubing / conduit manufactured from a flame retardant polyethylene resin rated as V2 according to UL-94

| Performance Enhancers | |||

| Flame Retardant | Yes | ||

| UV Inhibitor | No | ||

| Heat Stabilizer | Yes | ||

| Performance Characteristics | |||

| Flexibility | Excellent | ||

| Abrasion Resistance | Good | ||

| Chemical Resistance | Good | ||

| Recommended Operating Upper Temperature | +200°F (93°C) | ||

| Recommended Operating Lower Temperature | -40°F (-40°C) | ||

| Typical Physical Properties | Test Method | Value | Units |

| Specific Gravity/Density | ASTM D792 | 1.005 | - |

| Elongation @ Break | ASTM D638 | 945 | % |

| Elongation @ Yield | ASTM D638 | 167 | % |

| Tensile Strength @ 25C | ASTM D638 | 14.99619 | MPa |

| Flexural Modulus | ASTM D790 | 240 | MPa |

| Melting Point | ASTM D3418 | 239 (115) | °F (°C) |

| Notched Izod Impact Test | ASTM D256 | 10 | ft lb/in |

| Heat Deflection Temperature @66psi | ASTM D648 | 122 (50) | °F (°C) |

| Heat Deflection Temperature @264psi | ASTM D648 | 104 (40) | °F (°C) |

| Material Certifications | |||

| Underwriters Laboratory | UL-94 V2 @ 1.5 mm | ||

| FMVSS 302 | Max. Burn rate of | 101.2mm / min. (1.0 mm thick)Self-extinguishing | |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Q: How do you measure the diameter of your wire loom?

A: All of the wire loom we sell is measured by its inside diameter.

Q: Is this Tubing Split

A: Yes, this tubing has a slit down its center to allow for easy installation

Q: Is this tubing flexible?

A: While this wire loom does provide ample protection it also remains easily flexible and can be manipulated.

Videos

Return Policy – ( WIRE LOOM TUBING)

30-DAY RETURN POLICY

-

You may return your purchase within 30 days after delivery for a full refund less shipping charges.

-

Items must be in their original condition, not visibly used damaged, or cut.

-

10 foot Cut length wire loom orders are NON-CANCELLABLE & NON-RETURNABLE

-

GAYLORD bulk box orders NON-CANCELLABLE & NON-RETURNABLE

RETURN INSTRUCTIONS

Please Fill out our Linked RMA FORM to obtain a Return Authorization (RMA#) & Shipping instructions.

Let us know your Order ID, Name & which items you want to return.

Once we get your request we'll email you a Return Authorization and Shipping Instructions.

After we receive the return, it takes 3-5 business days for us to verify the items & process a refund. We'll refund back to your method of payment.

RETURN SHIPPING

-

Shipping charges are not refundable & customer is responsible for cost of return shipping.

-

We recommend you return via UPS, FedEx, or insured US Mail with a tracking number. Items not received by us will not receive a credit.

-

Shipping charges will apply on any exchanges.

SHORTAGE OR INCORRECT ORDERS

All claims for shortage or incorrect orders must be reported to us by phone or email within 5 business days from receipt of the order. Please mention your Purchase Order ID, Items, and your name.

DEFECTIVE PRODUCTS

Defective products must be reported to us within 30 days of delivery via phone or email.

Gaylord quantities are generally made to order, Lead times may apply.

Note: Gaylords Ship By LTL Pallet Freight Only

.jpg)